· articles · 3 min read

Oxygen Sensor Calibration Best Practices

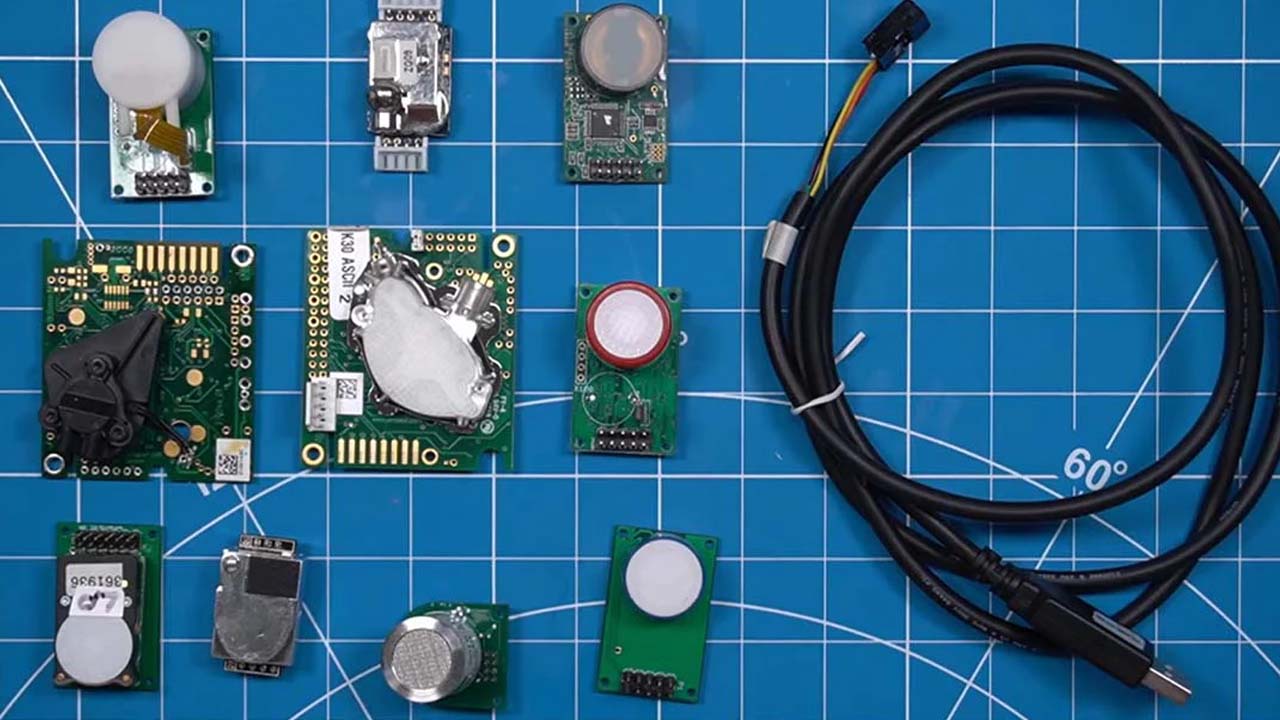

Since oxygen sensors are used in such a wide range of critical applications, calibration is essential to correct drift over time and guarantee highly repeatable measurements.

There is no single set of instructions suitable for calibrating oxygen sensors: best practices vary between device types and different manufacturers. Despite this diversity, all methods of oxygen sensor calibration typically adhere to a set of underlying principles. Essentially, the sensor is exposed to a calibration standard of known value and the reading is adjusted accordingly to achieve an ideal response.

Why Carry Out Oxygen Sensor Calibration?

Brand-new oxygen sensors come factory calibrated, but in order to ensure the best possible response in critical applications and to correct drift over time, it is important to calibrate the sensor within its end-use system. This means running standardized calibration tests periodically to maintain the sensor’s precision and resolution, thus maintaining its accuracy by guaranteeing highly repeatable measurements at your desired resolution.

The method of calibration used depends on various interconnected factors, including the number of relevant measurement parameters. For example: Dissolved oxygen sensors are often subject to one-point calibration in 100% air-saturated water which demands careful control/understanding of three key variables: barometric pressure, salinity, and temperature. Best practices for single-point dissolved oxygen sensor calibration include:

Ensuring the reference standard is neither over- nor under-saturated with oxygen

Maintaining consistent temperatures between the standard and the sensor

Accurately recording the barometric temperature at the time and place of calibration.

5-Points or Less: Oxygen Sensor Calibration

One-point oxygen sensor calibration is useful from a cost perspective as it is easy to create the right measurement environment. However, if your application demands accuracy at more than a single measurement level, one-point calibration will be insufficient. Two-point oxygen sensor calibration is slightly more complex as it uses two data points: A zero reference and a span. When acquiring a zero reference, it is important to eliminate residual air bubbles from the liquid standard and to once again ensure that the temperature is consistent.

Oxygen sensors that do not have a linear response across the measurement range may require some measure of algorithmic curve-fitting to match the actual response as closely as possible to the ideal response across the full measurement range. Most commercially-available oxygen sensors have characteristic curves with well-understood deviations from the ideal reading.

Most oxygen sensor calibration standards call for 5-points or less, which means users are often in the situation of having a few reference clusters relating to key parameters. This means you may have to carry out the bespoke characterization of your sensor in situ to derive the correct linearization formula.

Oxygen Sensor Calibration with Fusion Flow Technologies

Fusion Flow Technologies specializes in high-speed gas mixing with a suite of advanced gas mixers based on battle-tested mass flow controllers with industry-leading control response rates. This technology has proven to empower to professionals in the aquaculture industry who require a robust solution for multi-point gas sensor calibration based on bespoke models. If you would like to learn more, simply contact a member of the Fusion Flow Technologies team today.