Precision Gas Mixers

Gas mixers designed for hundreds of applications; from single recipe industrial high-flow operations, to highly complex research and development low-flow dilutions. Effortlessly create blends of up to 10 gases (pure or pre-mixed) at total flow rates from less than 10 SCCM to over 50,000 SLPM.

Features

What you get with MXM

Every MXM is hand-built in the USA and includes a brilliant 10.1" QLED touchscreen control interface packed with features to simplify your mixing operations

Lightning speed

Industry-leading control response time as low as 25ms* ensures accuracy and minimizes waste

Maximum efficiency

Custom-tuned MFCs prevent wasted gas at fluctuating pressures and flow rates

Extreme durability

Designed for 24-hour continuous operation in the most demanding industrial environments

NIST-traceable accuracy

As accurate as ±0.6% of the targeted mix percentage*

Unlimited flexibility

Mix up to 10 gases from the onboard library of 49 gases, with support for corrosives and refrigerants

Industry 4.0 ready

Monitor and control your gas mixer from anywhere and integrate with your existing cloud services

Max Channels

Max Flow (SLPM)

Max Pressure (PSIG)

Pre-Loaded Gases

Automation and scripting

MXM is the industry’s first IoT-ready gas mixer with advanced connectivity features allowing you to monitor, automate, and control the system from any device with a web browser.Built-in scripting

Use the built-in scripting system to simplify repetitive tasks and execute automatically based on conditions you define

Web API

The REST API further extends automation and integration of your gas mixer with your language and software of choice

RS-232

Control and monitor your gas mixer from microcontrollers, PLCs, or any RS-232 device that supports an ASCII interface

Digital+analog I/O

Communicate with any device using an analog signal and control relay circuits

Data logging

Save logs directly to the cloud, to an external storage device, or to the onboard flash memory - you have complete control over your gas mixer's dataMQTT

Push gas mixing status and measurements anywhere with the industry-standard lightweight MQTT protocol

Local CSV

Keep years* of detailed records of your mixing activity in the onboard 12GB of storage, or save to an external storage device

Network/Cloud Databases

Store logs in SQL and NoSQL databases on your local premises or in the cloud

Built with the best

Constant, accurate gas mixtures are delivered exclusively by MFCs from Alicat Scientific, renowned for their reliability, versatility and control response timeCustom-tuned Alicat MFCs

Gas control MFCs are match-tuned to provide mix accuracy during start up events, outlet pressure control capabilities, and rapid response to changing process conditions

Industry-leading response time

Control response time as low as 25 ms (dependent on flow rate, back-pressure and gas species)

Unrivaled versatility

Comes pre-loaded with 49 gas species and can be configured to support corrosive, refrigerant, and pre-mixed gases

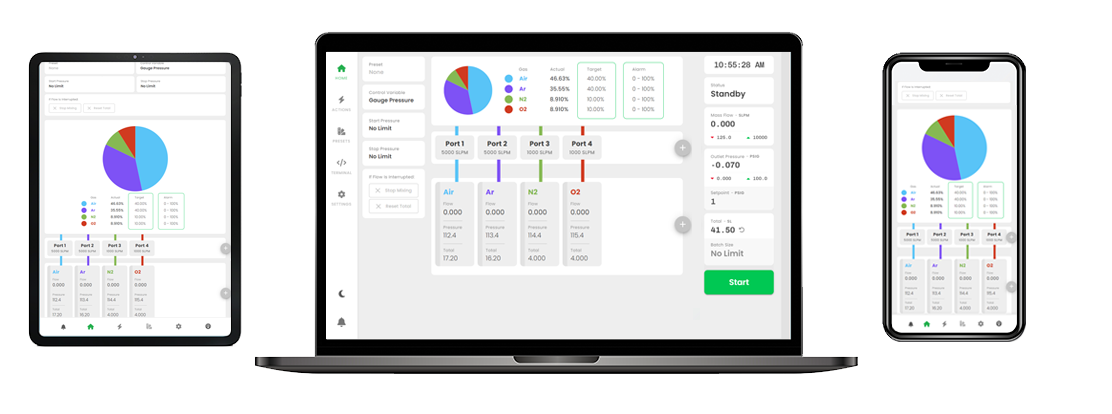

Control from anywhere

The complete control interface of MXM can be accessed remotely from any desktop or mobile device with a web browser. Remote sessions are enabled for your local network by default, and can be configured to work over the internet for complete control from anywhere in the world.

One size (never) fits all

MXM is available in three form factors to fit seamlessly into your existing process with minimal integration effort. All models feature a high-definition 10.1" capacitive touchscreen control interface and are built in a rugged, heavy-gauge steel frame.

- 1

Turn-key

Up to 6 low-to-medium flow MFCs are pre-installed inside the chassis with high quality stainless steel tubing and manifolds, for an all-in-one gas mixing lab in a box.

- 2

Stand-alone

Up to 10 MFCs with any flow rate are plumbed externally and managed by you, for ease of integration with your existing process requirements.

- 3

Rack-mounted

A 4U rack-mountable version of the standalone chassis optimized for environments with rack-mounted instrument panels

FAQs

Frequently Asked Questions

Is MXM a software-based gas mixer?

Can MXM be upgraded or reconfigured after purchasing?

Can MXM also add humidity to the mixed gas stream?

Does MXM allow for mixing fuel gases with oxidizing gases?

Can the same gas type be connected to more than one MFC control channel?

For example, Argon is assigned to a 5 SLPM unit as well as a 50 SLPM unit, allowing for a total possible Argon flow of 55 SLPM. Depending on the instantaneous requirement for Argon in the mixture, MXM will choose to utilize either (or both) controllers to meet the demand, with the best accuracy and control possible.

Can MXM change gas mixtures "on the fly"?

Is there an ATEX, Class I, Div II or Class I, Div I version of MXM?

However, please stay tuned to the upcoming release of Alicat’s intrinsically safe product line, which may allow Fusion Flow to offer a stand-alone MXM classified gas mixing system in the future.

Are pure gases required for proper operation, or can pre-mixed, multi-component gases also be used with MXM?

Essentially, MXM can track up to ten elemental gases, whether they’re coming into the instrument on ten individual pure feed sources, or by only two pre-blended, five-component sources.

Can MXM create more than one mixture at a time?

Can MXM handle corrosive/refrigerant gases?

What are the wetted materials inside MXM?

Standard MC Series (Low Flow)

Standard MC Series (Mid Flow)

Standard MC Series (High Flow)

Corrosive/Refrigerant MCS Series

Specifications

| Turn-key | Remote (Benchtop) | Remote (Rackmount) | |

|---|---|---|---|

| Dimensions | |||

| Height | 233.68 mm / 9.2" | 233.68 mm / 9.2" | 177.90 mm / 7.0" |

| Width | 355.60 mm / 14.0" | 297.18 mm / 11.7" | 482.60 mm / 19.0" |

| Depth | 360.68 mm / 14.2" | 185.42 mm / 7.3" | 180.98 mm / 7.1" |

| Turn-key | Remote | |

|---|---|---|

| Mechanical | ||

Max Inlet Pressure *High-pressure systems only, requires approval | 145 PSIG / 305 PSIG* | 145 PSIG / 305 PSIG* |

Min Operating Temperature | -10° C / 14° F | -10° C / 14° F |

Max Operating Temperature | 60° C / 140° F | 60° C / 140° F |

Weight | 20.9 kg / 46.0 lb | 4.5 kg / 10.0 lb |

| Gas Ports | ||

Connector Type *¼" tube used on channels with low flow | ⅜" Compression tube ¼" Compression tube* | NPT, SAE, VCR, VCO, BSPP, Compression tube |

Min Channels | 2 | 2 |

Max Channels | 6 | 10 |

| Power | ||

Max Power Consumption *Assuming largest MFCs at maximum flow | 1.56A @ 24VDC | 20A @ 24VDC |

Power Supply Input | 110-230 VAC 50-60 Hz | 110-230 VAC 50-60 Hz |

Power Supply Output | 3.75A @ 24 VDC | 6.67A @ 24 VDC |

| Sensor and Control Performance | ||

Mix Accuracy *In optimal conditions | ±0.6% of target mix percentage* | ±0.6% of target mix percentage* |

Repeatability 2σ (<= 20 SLPM Channels) | ±0.1% of reading + ±0.02% of full scale | ±0.1% of reading + ±0.02% of full scale |

Repeatability 2σ (50-1500 SLPM Channels) | ±0.2% of reading + ±0.02% of full scale | ±0.2% of reading + ±0.02% of full scale |

Min Full Scale Range (per channel) | 100 SCCM | 100 SCCM |

Max Full Scale Range (per channel) | 100 SLPM | 5000 SLPM |

Control Response Time *Dependent on flow rate, gas species, and back-pressure | 25 ms* | 25 ms* |

| Display | ||

Diagonal Size | 10.1" | 10.1" |

Height | 127 mm / 5" | 127 mm / 5" |

Width | 225 mm / 8.9" | 225 mm / 8.9" |

Panel | QLED | QLED |

Resolution | 1280 x 720 | 1280 x 720 |

Viewing Angle | 170° | 170° |

Max Brightness | 500 cd/m² | 500 cd/m² |

Touchscreen | Capacitive Multi-touch | Capacitive Multi-touch |

| I/O Ports | ||

USB 2.0 | 2 | 2 |

USB 3.0 | 2 | 2 |

Gigabit Ethernet | 1 | 1 |

Pre-Installed Gases

| Name | Formula | CAS Number |

|---|---|---|

| Air | ||

| Argon | Ar | 7440-37-1 |

| Methane | CH4 | 74-82-8 |

| Carbon Monoxide | CO | 630-08-0 |

| Carbon Dioxide | CO2 | 124-38-9 |

| Ethane | C2H6 | 74-84-0 |

| Hydrogen | H2 | 1333-74-0 |

| Helium | He | 7440-59-7 |

| Nitrogen | N2 | 7727-37-9 |

| Nitrous Oxide | N2O | 10024-97-2 |

| Neon | Ne | 7440-01-9 |

| Oxygen | O2 | 7782-44-7 |

| Propane | C3H8 | 74-98-6 |

| n-Butane | nC4H10 | 106-97-8 |

| Acetylene | C2H2 | 74-86-2 |

| Ethylene (Ethene) | C2H4 | 74-85-1 |

| iso-Butane | iC4H10 | 75-28-5 |

| Krypton | Kr | 7439-90-9 |

| Xenon | Xe | 7440-63-3 |

| Sulfur Hexafluoride | SF6 | 2551-62-4 |

| Deuterium | D2 | 7782-39-0 |

Corrosive Gases

Systems can be configured to support corrosive gases

| Name | Formula | CAS Number |

|---|---|---|

| Ammonia | NH3 | 7664-41-7 |

| Chlorine | Cl2 | 7782-50-5 |

| Hydrogen Sulfide | H2S | 7783-06-4 |

| Sulfur Dioxide | SO2 | 7446-09-5 |

| Propylene | C3H6 | 115-07-1 |

| 1-Butene (Butylene) | 1Buten | 106-98-9 |

| cis-Butene | cButen | 590-18-1 |

| iso-Butene | iButen | 115-11-7 |

| trans-Butene | tButen | 624-64-6 |

| Carbonyl Sulfide | COS | 463-58-1 |

| Dimethylether | DME | 115-10-6 |

| Silane | SiH4 | 7803-62-5 |

| Nitric Oxide | NO | 10102-43-9 |

| Nitrogen Trifluoride | NF3 | 7783-54-2 |

Refrigerant Gases

Systems can be configured to support refrigerant gases

| Name | Formula | CAS Number |

|---|---|---|

| R-11 (Tricholorofluoromethane) | CCl3F | 75-69-4 |

| R-115 (Chloropentafluoroethane) | C2ClF5 | 76-15-3 |

| R-116 (Hexafluoroethane) | C2F6 | 76-16-4 |

| R-124 (Chlorotetrafluoroethane) | C2HClF4 | 2837-89-0 |

| R-125 (Pentafluoroethane) | CF3CHF2 | 354-33-6 |

| R-134A (Tetrafluoroethane) | CH2FCF3 | 359-35-3 |

| R-14 (Tetrafluoromethane) | CF4 | 75-73-0 |

| R-142b (Chlorodifluoroethane) | CH3CClF2 | 75-68-3 |

| R-143a (Trifluoroethane) | C2H3F3 | 420-46-2 |

| R-152a (Difluoroethane) | C2H4F2 | 75-37-6 |

| R-22 (Difluoromonochloromethane) | CHClF2 | 75-45-6 |

| R-23 (Trifluoromethane) | CHF3 | 75-46-7 |

| R-32 (Difluoromethane) | CH2F2 | 75-10-5 |

| RC-318 (Octafluorocyclobutane) | C4F8 | 115-25-3 |

Add-ons + Accessories

USB-powered digital I/O module with 4 inputs / 4 outputs

USB-powered analog I/O module with 4 inputs / 2 outputs

Stainless steel ballast cylinders in 6 different sizes

Stainless steel static mixing tubes in various lengths and diameters

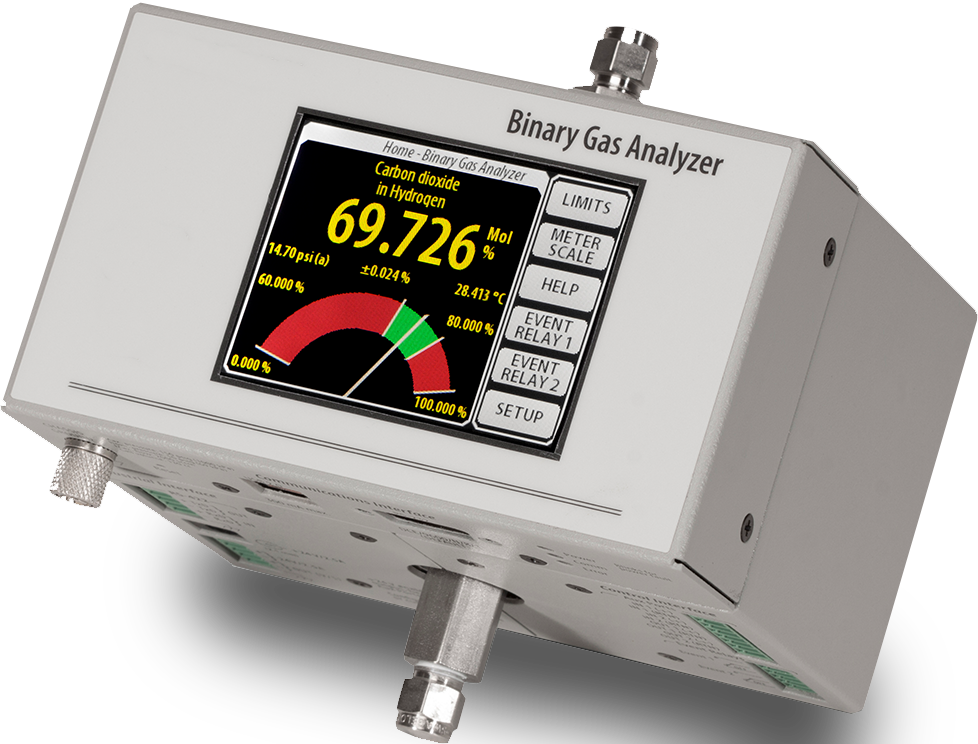

High-accuracy binary gas analyzer for 2-gas blends

Rugged and high-quality Pelican cases custom-fitted for MXM systems

Questions? We have answers.

Chat for free with a gas mixing expert about your application today.